Micro electron beam welding

Electron beam welding is a fusion welding process where the heat is generated by the impact of electrons emitted and accelerated by an electron gun. The emission, the acceleration and the trajectory of the electrons is performed under vacuum. Welding under vacuum has the important advantage that no oxidation or interaction with oxygen or hydrogen occurs. This is ideal for welding materials that oxidize very quickly such as tungsten, titanium, molybdenum, zirconium, which e.g. are used in the aircraft and space industry.

The automotive sector is also interested in this technique: minimal distortion is a big advantage for series production of gears of gearboxes. Electronic components can also be welded with electron beam welding due to the high precision and low heat input, providing that the electronics remains protected. At a few millimeters away from the weld, there is no thermal influence. It is also possible to weld dissimilar metals using this technique.

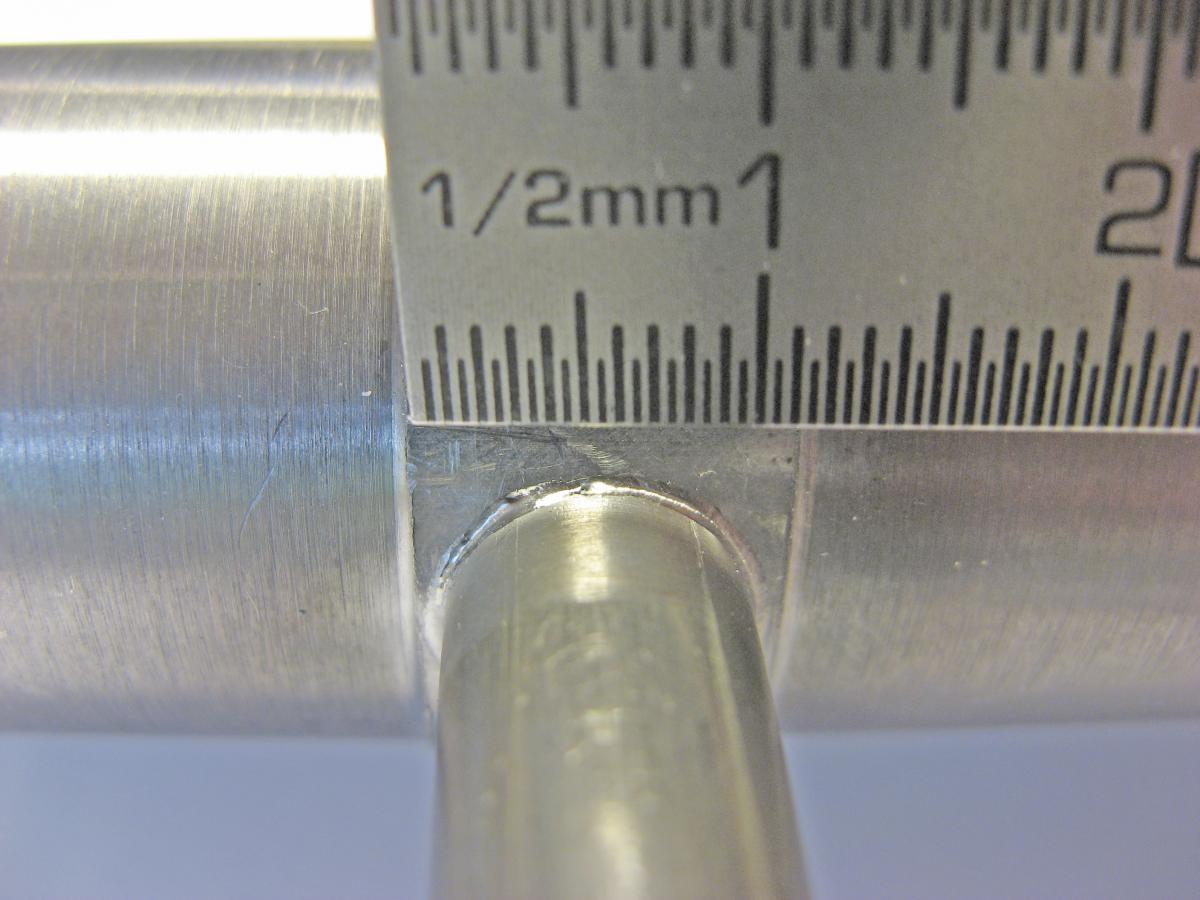

Weld of a tube in tantalium with a thicknes of 0,5 mm.

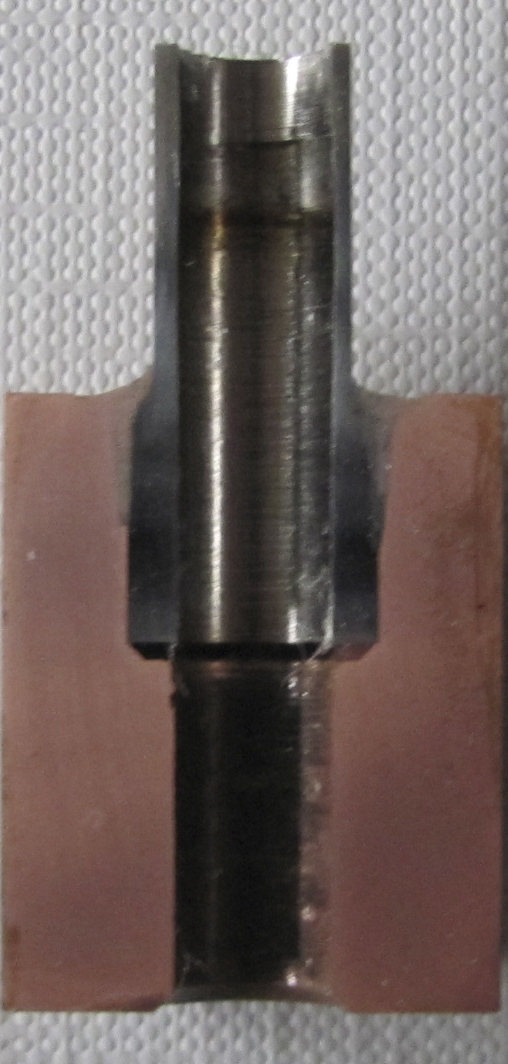

Weld of a stainless steel tube (diameter 8 mm - wall thickness : 1 mm) to a cylindrical copper part