MAGPULS : Electromagnetic pulse forming

Principle of magnetic pulse forming

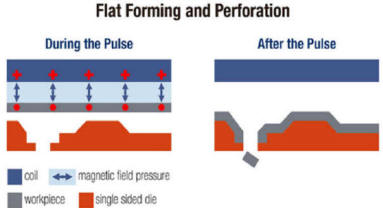

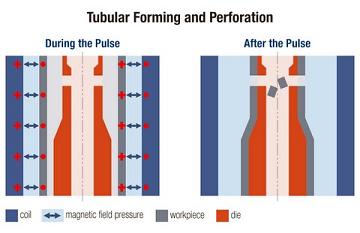

A high energy current is discharged through a coil surrounding the workpiece (in tubular applications) or covering it (in flat applications). This intensive high current creates electromagnetic forces between the coil and the workpiece which accelerates the workpiece towards a single side die. The workpiece is shaped to the die, perforated and cut into the required shape, in a single operation.

|

|

|

|

|

Applications of electromagnetic pulse forming and crimping

Automotive industry :

- drive shafts

- components of air conditioning

- fuel filters

- closing caps of cylindrical components

- coatings of exhaust systems

- (simultaneously) forming and perforating aluminium tubes (e.g. for car seats)

Electrical sector :

- electric fuses

- components of electric motors

- cable ducts

HVAC - industry: Heating, Ventilating, and air Conditioning :

- components of cooling units, air conditioning, cooling tubes (as a replacement of e.g. brazing or mechanical joining techniques)

Nuclear industry

Aerospace industry:

- components of planes : drive shafts, lining of ammunition, control rods

- components of fuel pumps

|

|

|

|

Advantages of magnetic pulse forming

Magnetic pulse forming offers a number of advantages with regard to other deformation techniques :

- Reproducibility: Since the electric energy in the coils can be controlled very precisely, the reproducibility is very high.

- Without contact : In contrast to traditional deformation techniques, the magnetic fields generate the forces. No lubrication is necessary and since this technique operates without contact, the damage which can be caused by a former in the conventional method can be avoided. Surface treated materials (e.g. anodising) can be formed, without damaging the surface layer.

- Spring-back : The material is deformed plastically, resulting in a permanent plastic deformation, where spring-back of the deformed material is avoided.

- The process ensures a higher formability of the workpieces due to the lower internal stress and friction, in comparison with other mechanical forming processes. Workpieces which must be stress-relieved in conventional forming processes, can be formed with magnetic pulse forming in a single step.

Research needs

Nowadays, due to the increasing international competition, companies need faster and more economic production techniques and are forced to decrease the production costs to remain competitive. The largest impact can be expected of a productivity increase by using new innovative production techniques. The above described production process offers a number of interesting possibilities.

Very little objective knowledge is available concerning the technical feasibility of the use of this process for relevant industrial applications, nor concerning the possible increase of productivity or the quality, and therefore concerning the economic advantages that the use of this innovative process can lead to.

Project goals

The research centre of Belgian Welding Institute together with OCAS and UGenthave investigated this production technique and have demonstrated the potential advantages for the industry. By participation in this research project, companies got an insight in the possibilities of the new process. They were able to assess if this process is usable for their specific applications, taking into account the properties, the necessary investments, the profit increase in comparison with the current applied technique, the reliability of the processes, and so on…

Project description

Project type

Collective research project : studies and research which aim at at acquiring, joining and translating technological knowledge to useful innovation applications, and this in favour of a group of companies. The results of the research must lead to an economical and ecological profit for the participating companies. The obtained knowledge is also made available to other companies from the sector.

Project partners

- Belgian Welding Institute

- OCAS

- University of Ghent

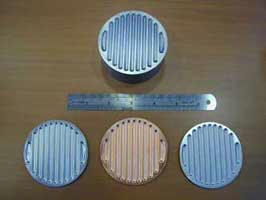

Magnetic pulse equipement available at the Belgian Welding Institute

- Click here for more information