DAHLIAS: Development and Application of Hybrid Joining in Lightweight Integral Aircraft Structures

Project goals

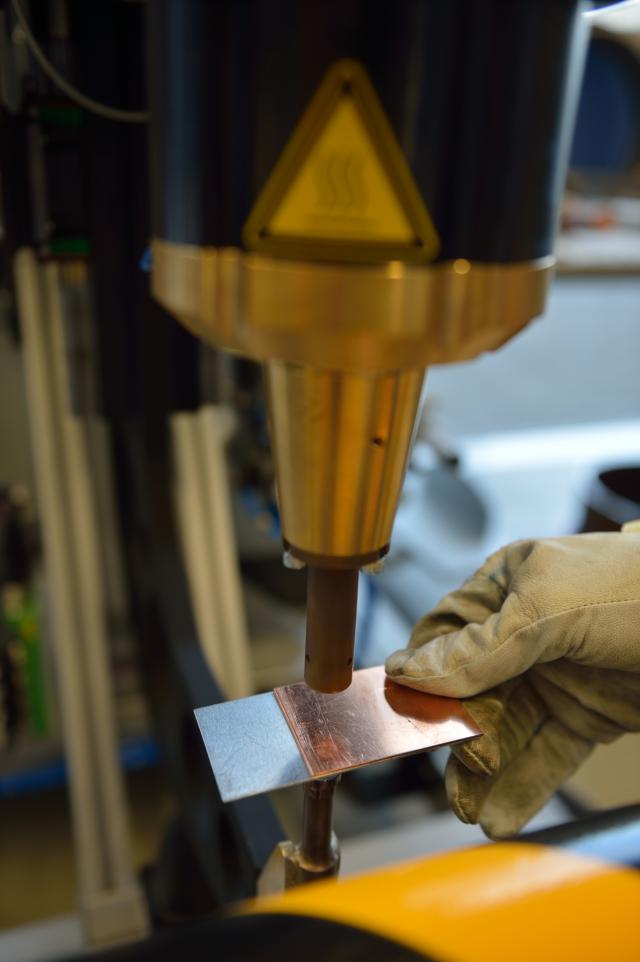

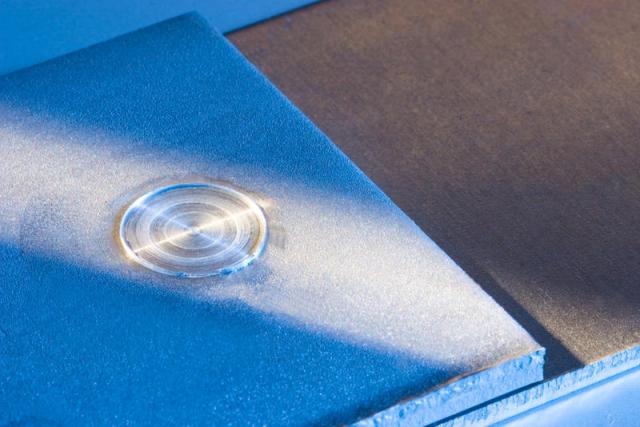

The main goal of the DAHLIAS project is to optimize hybrid connections (friction spot welding in combination with adhesives) for application in aircraft structures. Friction spot welding is a solid-state joining technique (no melting of the materials), especially suitable for joining lightweight alloys in similar and dissimilar material combinations. The process has already been successfully applied to difficult and non-weldable alloys and is considered a potential candidate for replacement of mechanical joining.

Overlap joints in aircraft structures require the use of a seal for corrosion protection. The use of a seal that also has an adhesive function would complement the high quality of the joints, not only for protection against corrosion, but also contribute to the overall mechanical behavior of the structure.

Project description

In order to achieve the aim of this project, a work plan has been drawn up, consisting of 8 work packages. Two work packages focus on developing the friction spot welding process using standard samples, with and without adhesive. In parallel, the adhesive / seal, including surface pretreatment, is developed.

The hybrid connections developed in this project will be compared with conventional connection technologies to demonstrate their potential. Quality control will be investigated through non-destructive testing and through process control based on inline monitoring of the welding parameters.

In the last phase of this project, demonstration pieces will be created to evaluate the potential of the proposed technology for aircraft structures.

The consortium consists of the Helmholtz-Zentrum Geesthacht (DE), the Belgian Welding Institute, Chemetall (DE), Institut de Soudure (FR), and TRA-C Industries (FR). The project is supported by the CleanSKy2 program of the European Commission (contract No. 821081).

Results

More information can be found on the project website