Electromagnetic pulse welding

Working principle

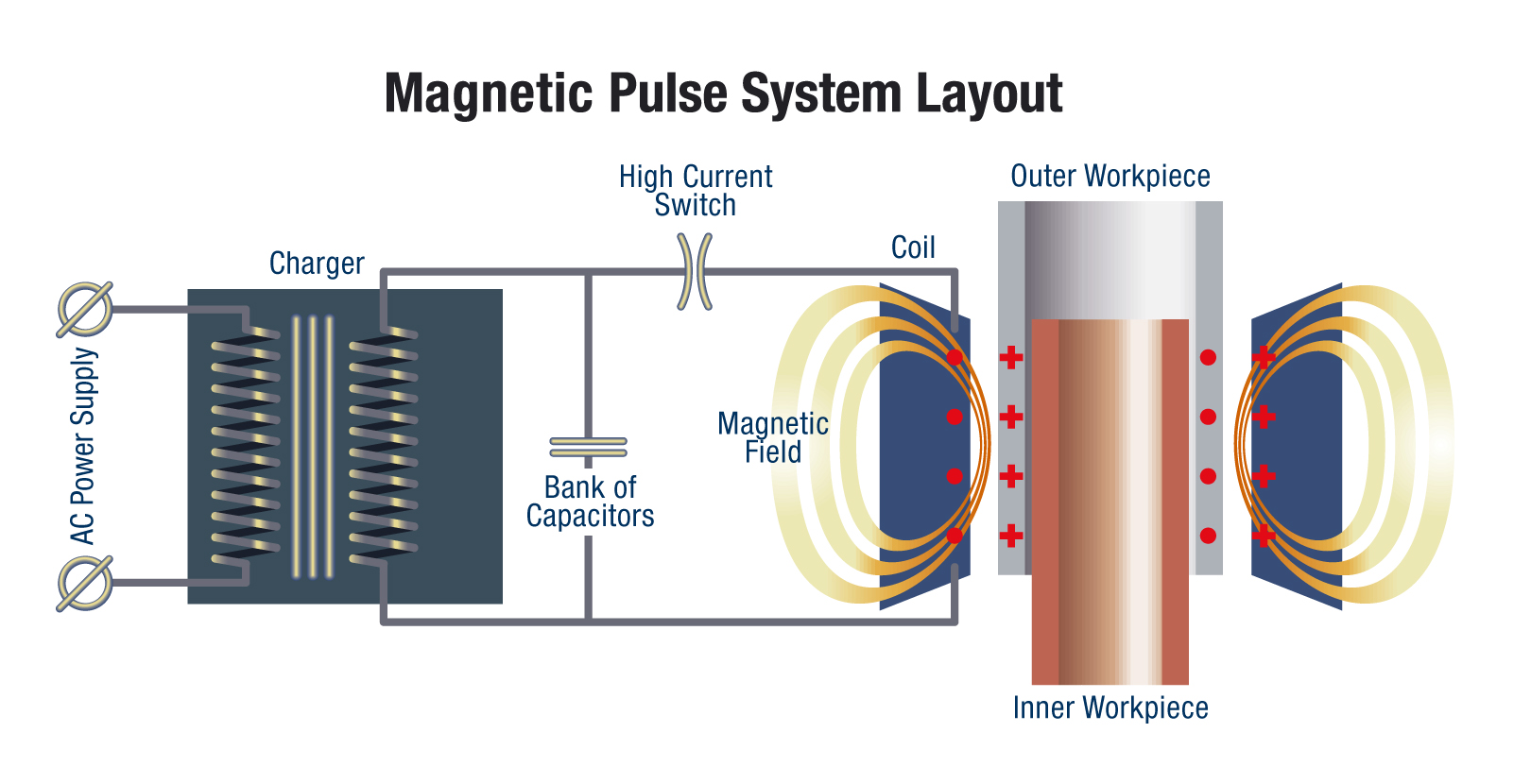

The basic principle is shown in the figure below. The workpieces are placed inside a coil. A large amount of energy is compressed and discharged in an extremely short period of time. Some systems can discharge up to than 2 millions amps in only 100 microseconds. The high energy flows in the coil, and the discharge of electric energy induces the so-called "eddy currents" in the external workpiece. Both currents (in the coil and in the external workpiece) induce magnetic fields, which oppose each other. The reaction forces between the opposing magnetic fields are forcing the external part towards the internal part at high velocity to cause welding. The impacting speed is more than 1000 km/h. This results in a permanent distortion, without spring-back of the workpiece.

The actual process lasts no longer then 100 microseconds. No protecting atmosphere, filler materials or other aiding materials are necessary. The magnetic pulse welding process is a "cold" welding process, the material does not get warmer than 30°C. Due of this, no heat affected zone is created, and the metal is not degraded. The weld becomes the strongest part of the assembly.

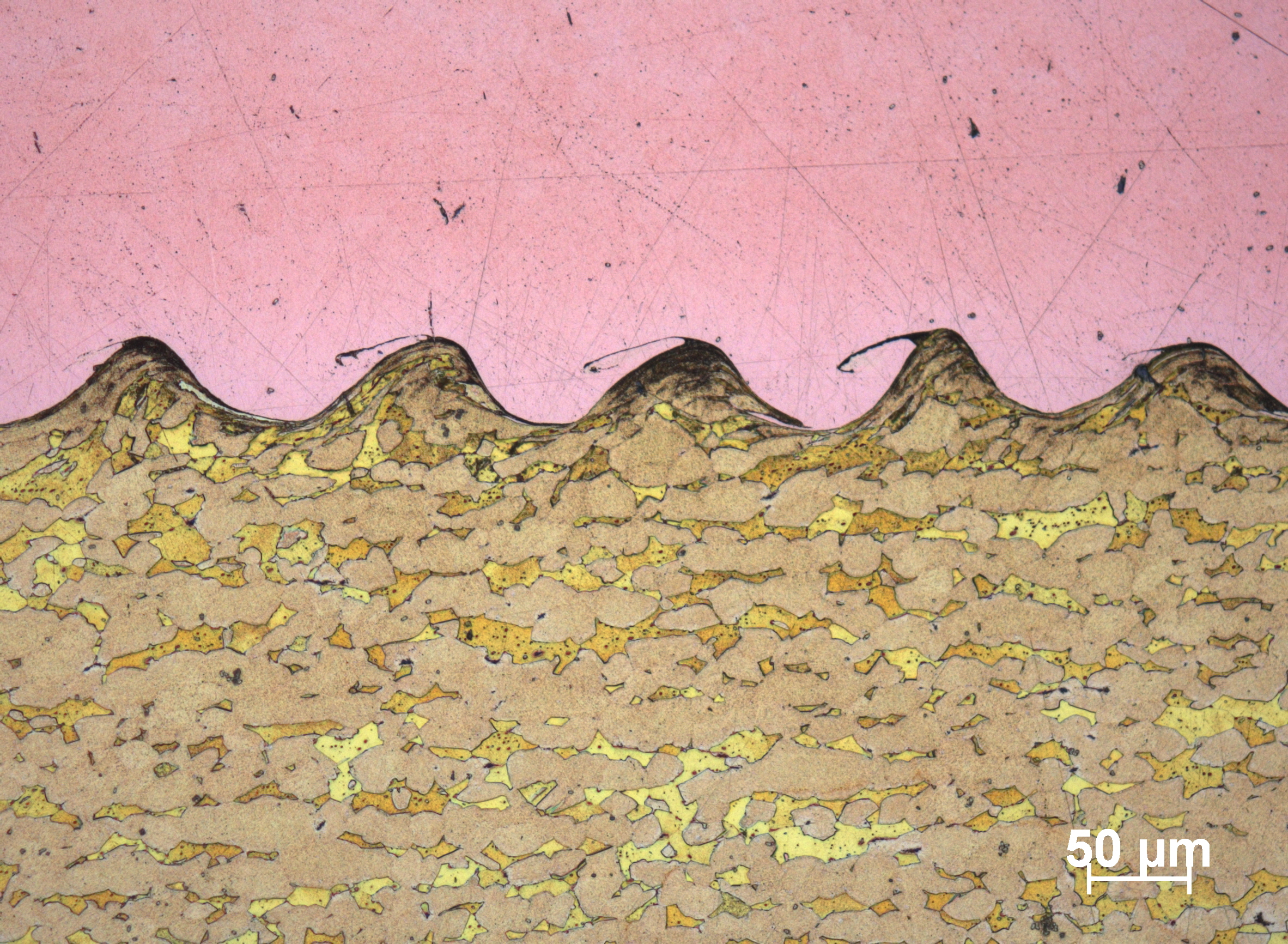

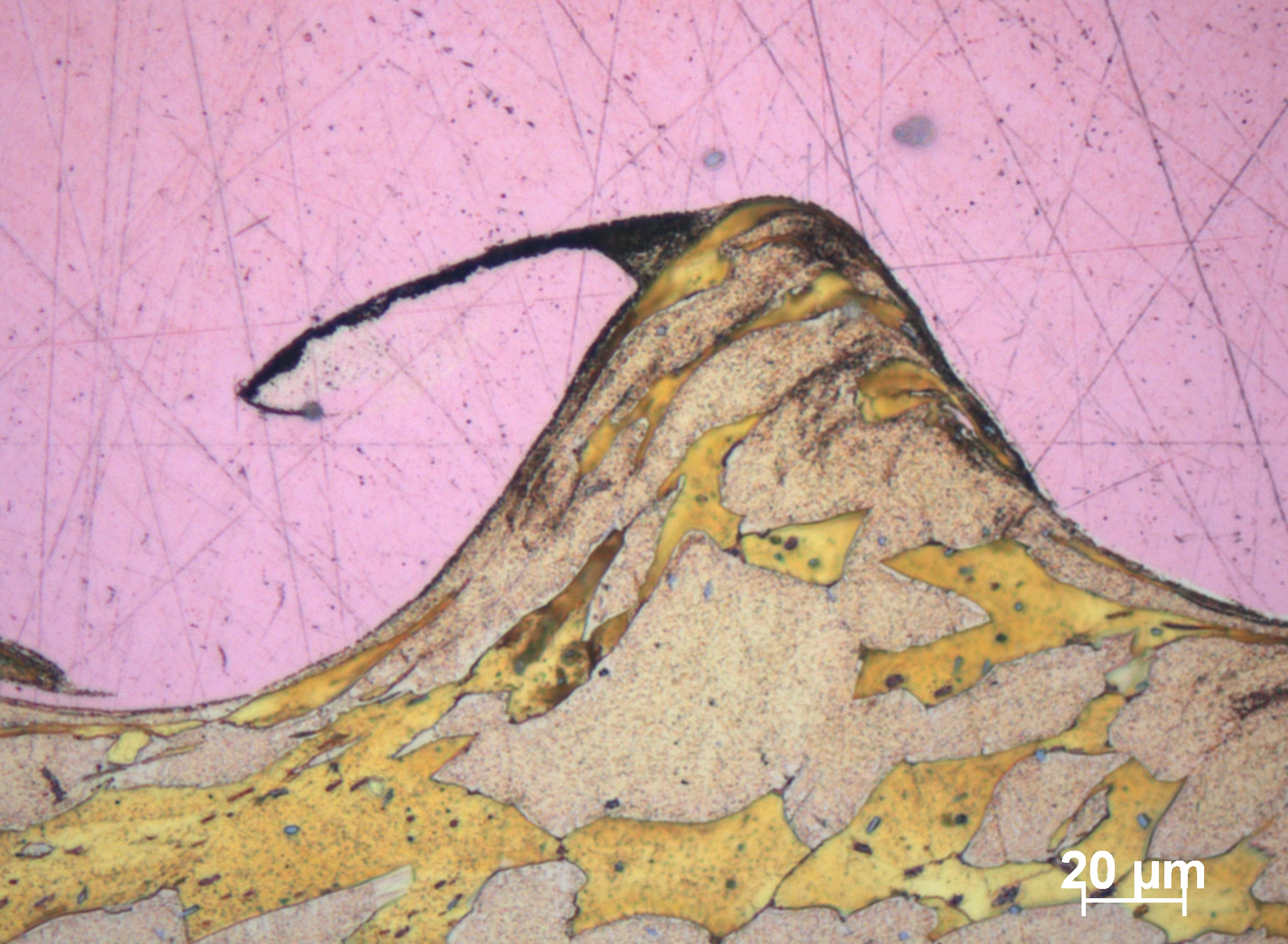

No shielding gases, filler materials or other auxiliary materials are required. The magnetic pulse welding process is also a "cold" welding process, the heat generation is very limited. This will create no heat-affected zone and the material properties in the weld zone are not changed. The absence of heat during the weld cycle allows to connect materials with a strongly different melting point. It is e.g. possible to join aluminum to copper, aluminum to steel or copper to brass. A microscopical picture of a weld cross section shows many similarities with that of an explosion-welded connection.

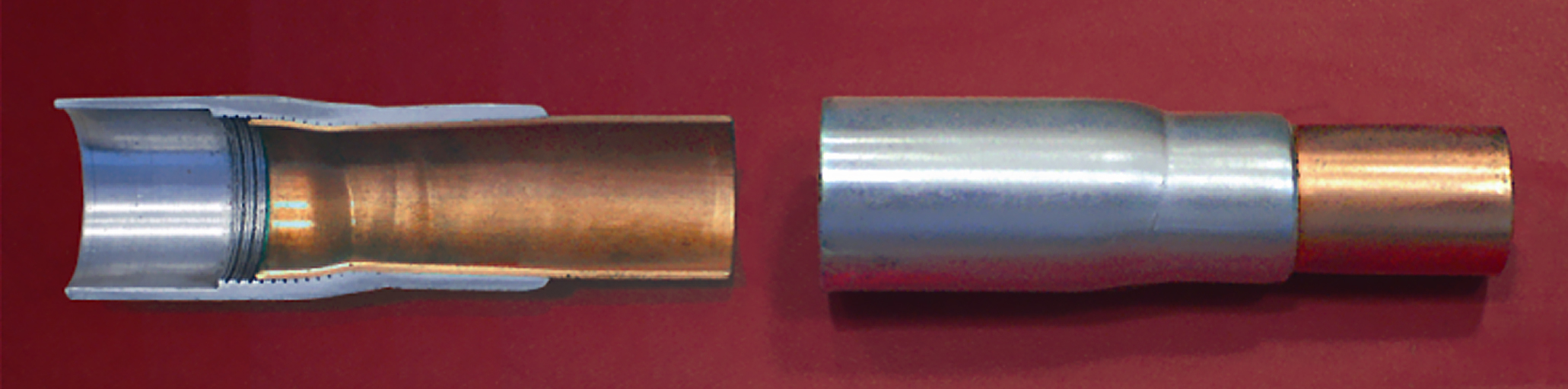

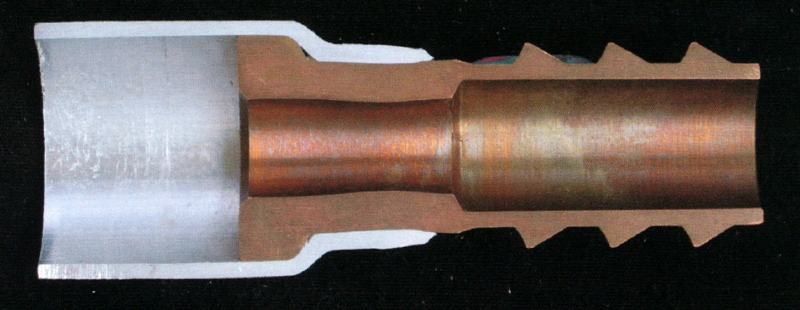

Connection of copper to aluminium tubes

|

|

Interface of a copper-brass weld

Equipment

Equipment for magnetic pulse welding consists of the following components:

- a high-voltage transformer,

- the capacities, in which the electrical energy is stored,

- the coil for welding,

- a transformer coil, with which the frequency and amplitude of the electric current discharge can be adjusted.

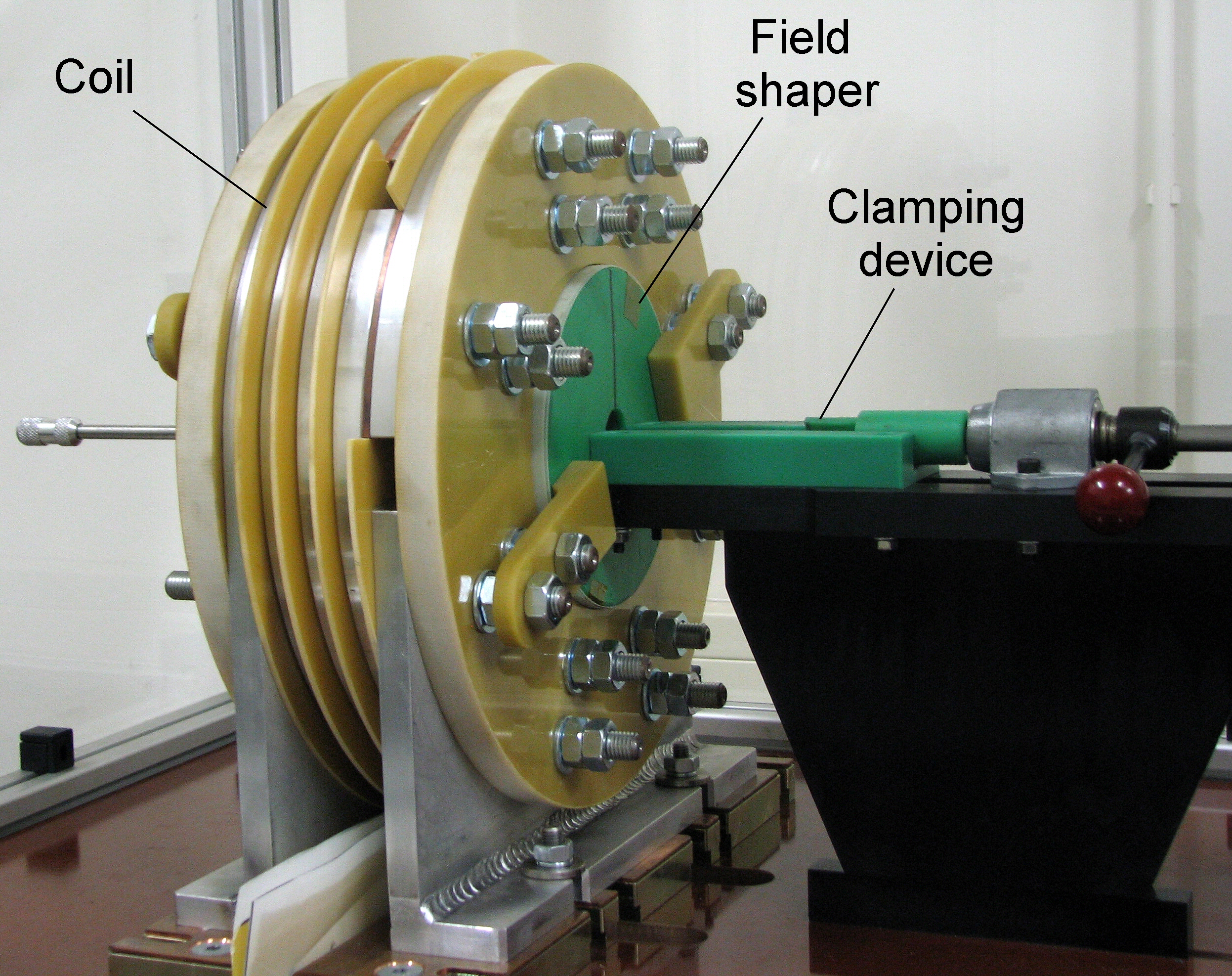

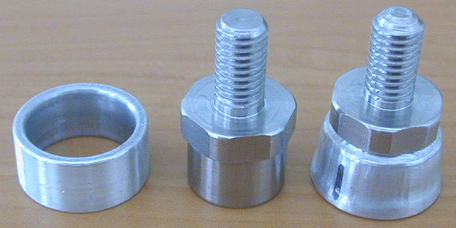

BWI has a test setup that allows to investigate the applicability of the process for certain applications. The maximum energy of the welding machine is 50 kJ with a charging voltage of 25 kV. The following figure shows the coil in conjunction with the field shaper.

Advantages and limitations of the magnetic pulse welding process

- The weld is stronger than the weakest base material : during material testing the crack appears outside the weld area.

- A protecting atmosphere, filler materials or other aid materials are not necessary.

- Magnetic pulse welding is a "cold" welding process, the parts are not heated. Therefore no heat affected zone is created, and no loss of material properties takes place. This also means that the welded workpieces can be unclamped immediately after welding and can be further processed immediately.

- High production speed, sometimes up to 10 pieces per minute.

- It is an ecological welding process, since no heat, radiation, gas or welding fumes are produced.

A condition for magnetic pulse welding is that the material to be deformed needs to possess a good electrical conductivity. If this is not the case, the required energy to deform or weld the material increases. Another condition is that the surfaces to be joined need to be positioned in the overlap configuration.

Materials

The process can be used for joining cylindrical or flat workpieces in the overlap configuration. The absence of heat during the weld cycle makes it possible to join dissimilar materials. Until now a small number of material combinations has been examined. Magnetic pulse welding has been successfully used in welding aluminium to steel. Also other dissimilar and similar metals that have been welded successfully (see table below).

This joining technique is adaptable to a wide variety of electrical conductive materials. Less conductive materials require a higher energy. The cross section of a weld shows many resemblances with this of an explosion weld.

Possible material combinations are :

- aluminium to aluminium

- aluminium to copper

- aluminium to magnesium

- aluminium to titanium

- copper to copper

- copper to steel

- copper to bronze

- nickel to titanium

- nickel to nickel

- steel to steel

Joining of dissimilar materials

Applications can be found for joining materials that are difficult to join with the conventional welding techniques. For example, copper and aluminium are materials which are usually joined by brazing or soldering, but these processes are labour intensive and therefore expensive. Other sectors that invetigate the use of the process for their applications are the aerospace and the nuclear sector, where very specific heat-resistant materials are used.

Other applications are the copper pipes in refrigeration systems, which can be welded with this technology.

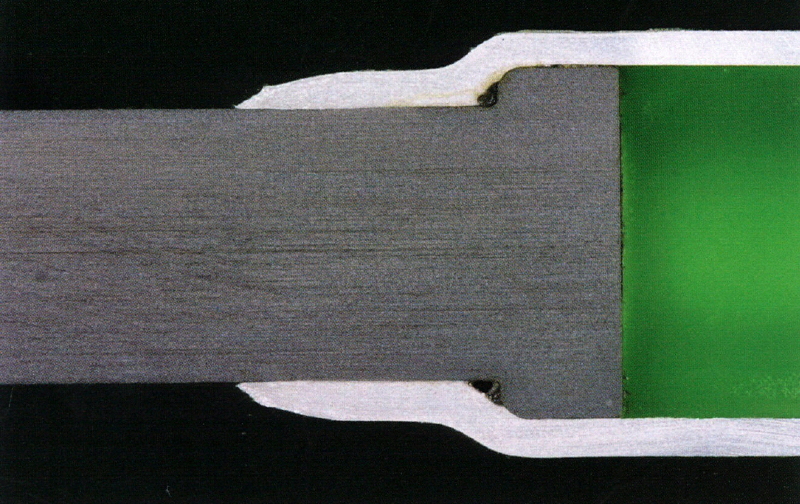

|

|

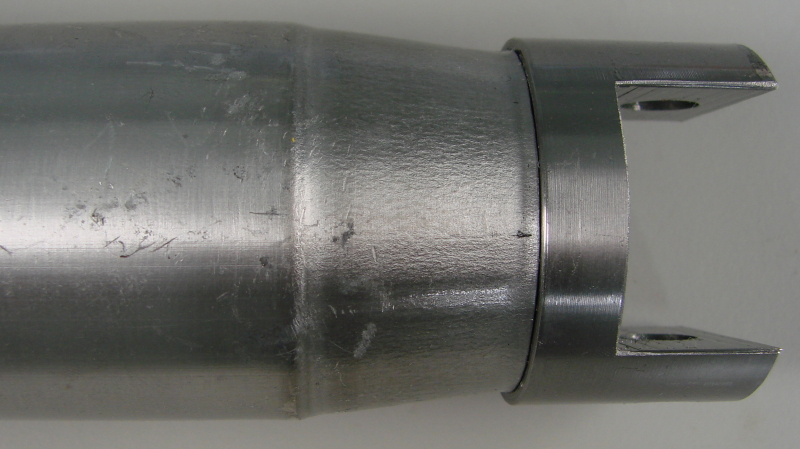

Aluminium-copper and aluminium-steel (Source: BWI & SLV München

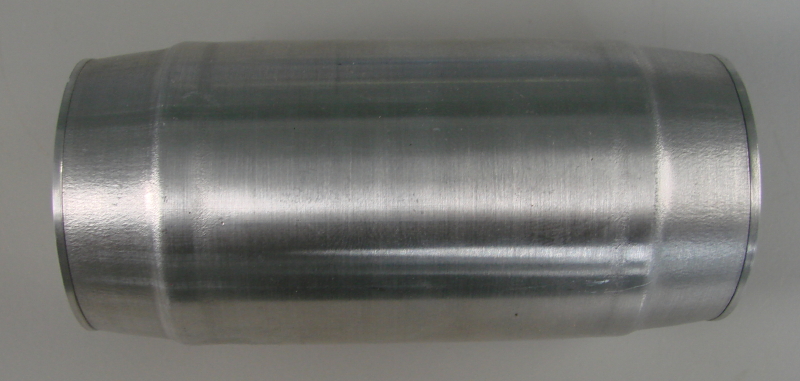

The welding process lends itself especially for the production of niche products or large series. For example, components for the air conditioning industry, where copper pipes with flanges in stainless steel have to be connected. Currently, these joints still need to be brazed. Other possible applications are pressure vessels for air conditioning systems in passenger cars or fuel filters. The following figure shows an electromagnetic pulse welded pressure vessel made of an aluminium tube and two aluminium end pieces. The welds in this vessel are helium-proof and resistant to the very high pressure of the air conditioning systems.

Electromagnetic pulse welded pressure vessel for airconditioning systems (Source: PSTProducts)

Aluminium-Stainless steel (Source: BMax)

|

|

Magnetic pulse welding versus MIG/MAG welding (components of airconditioning systems)

Magnetic pulse welded driveshaft (aluminium – steel joint)

(Source: PSTproducts)